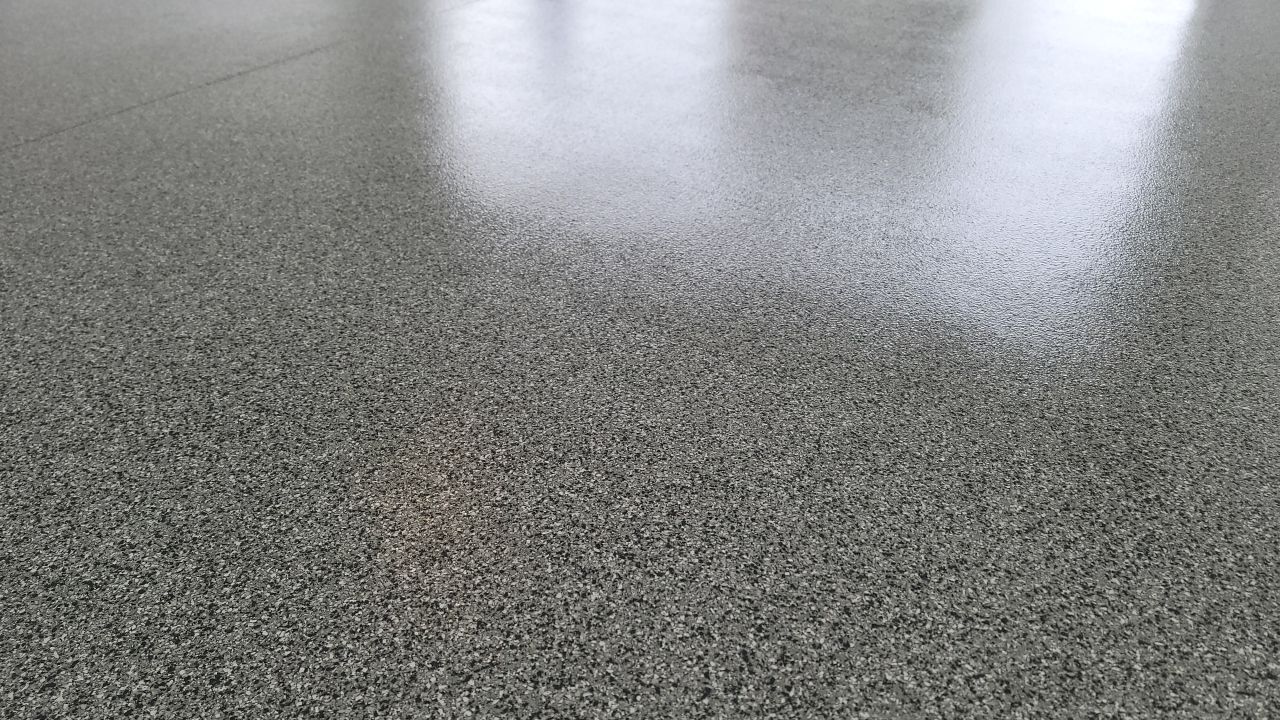

Are Epoxy and Polyurea Floors Waterproof?

Key Takeaways

- Epoxy and polyurea are highly water-resistant at the surface, but they don’t make porous concrete or joints “waterproof.”

- Real success comes from prep and detailing (grinding, crack/joint treatment, clean edges) plus simple habits—squeegee meltwater, remove salt film, and avoid long-term puddles—especially in Pennsylvania’s freeze–thaw and salt season.

Short answer: they’re highly water-resistant on the surface, but they don’t make concrete itself waterproof. A quality epoxy or polyurea system sheds spills, car wash runoff, and winter slush with ease. What they don’t do is stop moisture vapor pushing up through a slab or water intruding at joints and edges. That’s why the best installs pair the right coating with smart prep, crack/joint treatment, and basic water management.

What “waterproof” really means on concrete

Concrete is porous. Even a great coating is still riding on top of a material that can absorb water and transmit vapor from below. Coatings protect the surface—they’re not a basement waterproofing membrane. If your slab has active vapor drive, hydrostatic pressure, or recurring liquid seepage, those issues must be addressed first (drainage, vapor testing, mitigation primers) or any coating can be stressed.

Epoxy: excellent surface protection, rigid by nature

High-quality epoxies form a dense, continuous film that’s very resistant to standing water, common household chemicals, and road grime. The limitation is rigidity: when concrete moves with freeze–thaw or minor settlement, rigid films can micro-crack or lose edge adhesion. Epoxy also varies in vapor permeability—some systems breathe a bit, others are nearly vapor-tight—so matching the chemistry to the moisture profile of your slab matters.

Polyurea: built to flex and shrug off moisture

Polyurea systems, often finished with a polyaspartic topcoat, are known for fast cure, chemical resistance, and a touch of flexibility that helps them ride out temperature swings and micro-movement. That flexibility doesn’t turn them into a waterproofing membrane, but it does help the film maintain integrity when the slab expands, contracts, or sees a wet/dry cycle—useful in Pennsylvania garages where winters bring de-icing salts and spring brings damp air.

Where water actually sneaks in

Even the best coating can be undermined if water routinely works its way underneath. The usual suspects:

- Joints and cracks that weren’t cleaned, filled, or detailed properly.

- Perimeter edges where the coating meets base plates, stem walls, or the garage threshold.

- Negative slope that keeps puddles parked in the same place day after day.

A good install grinds the slab, repairs pits/cracks, treats control joints appropriately (full fill or neat, clean edges per design), and finishes edges cleanly so runoff can’t wick beneath the film.

Pennsylvania realities (subtle but important)

Winters track salt brine and slush into the first few feet of the garage; spring/fall bring humidity swings and occasional condensation on cool concrete. None of this is a problem for quality epoxy or polyurea if water isn’t sitting for days and joints are sealed correctly. A quick squeegee after storms, rinsing salt film mid-season, and keeping floor mats clean prevents long-term wet spots that can telegraph into the coating edge.

Everyday water vs. moisture vapor

It helps to separate two ideas:

Topical water (everyday spills): Coated floors handle buckets, snowmelt, and rinse water easily. You’ll see the liquid bead and move—exactly what you want.

Moisture vapor (from below): If your slab releases vapor, it can create blisters under nearly any tightly-sealing coating. Vapor testing before installation and, if needed, a compatible moisture-tolerant primer or remediation step is the right fix—not a thicker topcoat.

Care tips that keep coatings watertight at the surface

You don’t need special products—just a few habits that reduce standing moisture and residue:

- Squeegee or broom water toward the door after car washes or storms.

- Neutral-clean and rinse occasionally to remove salt film and soaps that attract moisture.

- Use containment mats at the threshold in winter; rinse them outside.

- Protect point loads (jack stands, motorcycle kickstands) so the film isn’t stressed at tiny contact points.

Choosing between epoxy and polyurea

If you’re mainly dealing with typical garage water—slush, wash water, occasional spills—either system performs well when installed properly. If your slab sees movement, heavy temperature swings, or you want the quickest return to service,

polyurea with a polyaspartic topcoat often provides the most forgiving, long-lasting result. If moisture from below is a concern, the deciding factor isn’t “epoxy vs. polyurea” as much as

prep and vapor mitigation before either goes down.

Frequently Asked Questions

Will a coating stop water coming up through my slab?

No. Coatings resist surface water; they don’t cure hydrostatic issues. Address drainage and vapor drive first, then coat.

Can I leave puddles on the floor?

Short-term puddles are fine. For best results—especially in PA winters—push meltwater out and don’t let salt brine sit for days.

Do flakes or traction additives affect water resistance?

No. They sit within or on the topcoat. Water resistance comes from the film build and chemistry, not the texture.

What if I already have a little moisture issue?

Get a moisture test. Many cases can be handled with the right primer or remediation step followed by your chosen system.