Best Garage Floor Coating for Cold Climates

Key Takeaways

- Cold climates expose epoxy’s weaknesses—rigidity, longer cure windows, and sensitivity to moisture—causing peeling and hot-tire pickup early in the coating’s life.

- Polyurea handles freeze–thaw cycles, road salt, and rapid temperature swings far better, making it the most reliable choice for Pennsylvania and other cold-weather regions.

A garage floor in a cold-weather state takes a beating—snowmelt, de-icing salts, road grime, freeze–thaw cycles, and wild temperature swings between seasons. Most homeowners start by looking at epoxy, and while it can work in mild climates, Pennsylvania’s winters expose the limits of a rigid coating fast.

Below, we break down how cold climates affect garage floors, where epoxy falls short, why polyurea rises to the top for long-term performance, and how to choose the right system for your home.

How Cold Weather Impacts Garage Floor Coatings

Concrete doesn’t stay still when temperatures drop. It expands, contracts, absorbs moisture, and releases it again—over and over. This movement creates conditions that make or break a coating:

Freeze–thaw cycles: Water in the slab expands when it freezes, stressing anything bonded to it.

Rapid temperature swings: Rigid coatings struggle when the concrete moves faster than they can flex.

Salt and slush: Meltwater carries de-icing salts that attack weak coatings and penetrate unprotected concrete.

Moisture vapor: Warm cars on cold floors create condensation under and on top of the coating.

Any coating that can’t flex, cure fast, or handle chemical exposure tends to crack, peel, or discolor in a single season.

Where Epoxy Struggles in Cold Climates

Epoxy looks great on day one, but cold-weather garages reveal its weaknesses quickly:

- Rigid composition: Epoxy can’t flex with concrete as it freezes and thaws, leading to micro-cracks and adhesion loss.

- Longer cure windows: Cold slows the cure dramatically; most epoxies can’t be installed reliably in winter without special additives.

- Hot-tire pickup: Warm tires on a cold slab can lift epoxy where the bond has weakened.

- Chemical sensitivity: Road salt, brine, and winter grime can stain or dull the finish.

- Moisture issues: If moisture vapor increases during seasonal shifts, epoxy is far more likely to bubble or peel.

If your goal is a short-term cosmetic refresh and timing lines up with warm weather, epoxy can be “good enough.” But for a floor you expect to survive multiple winters, epoxy’s limitations add up fast.

Why Polyurea Performs Best in Cold Climates

Polyurea is designed to move with concrete and shrug off winter conditions—exactly what Pennsylvania homeowners need. It’s the system we install most often because it reliably handles:

Flexibility in Freeze–Thaw

Polyurea has built-in elasticity, letting it expand and contract with the slab instead of resisting it.

Fast Cure in Low Temperatures

It cures faster and more consistently year-round, including shoulder seasons when temperatures swing from 30°F in the morning to 65°F by afternoon.

Superior Chemical Resistance

Road salt, snowmelt, gasoline, and winter grime won’t stain or attack a polyurea system the way they can with epoxy.

High UV Stability

Even garages with a lot of natural light won’t see the ambering or discoloration common with epoxy.

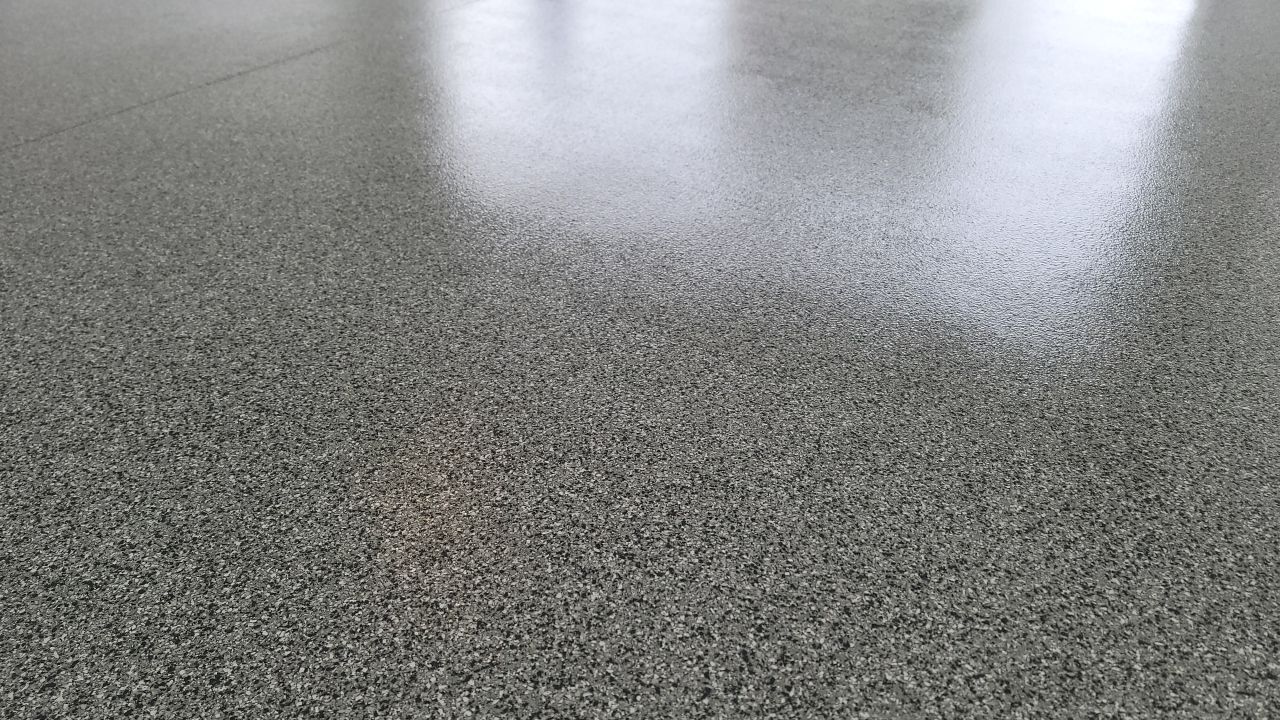

Better Traction Options

Textured flake systems create subtle grip—important when meltwater freezes overnight.

When long-term durability matters, polyurea is the most dependable cold-climate coating.

What a Professional Install Adds (Especially in Winter)

Cold climates magnify prep issues. A professional installation controls the variables epoxy kits can’t:

- Moisture testing to ensure the slab is safe to coat despite seasonal humidity swings.

- Mechanical grinding to create the proper bond profile—etching alone won’t hold up in winter.

- Crack, pit, and spall repair so freeze–thaw cycles don’t expose weak points underneath the coating.

- Correct curing windows with materials that actually perform in colder temperatures.

- Consistent flake broadcast and clean edgework for a finish that hides imperfections and looks great through every season.

You can see how we handle prep, coatings, and installation details on our garage floor coatings page.

Built for Pennsylvania Winters

Southeastern Pennsylvania sees everything from freezing rain to sub-zero nights to road-salt runoff. Those conditions are harsh on coatings—and even harsher on concrete underneath.

A polyurea system gives homeowners peace of mind because it:

- Resists hot-tire pickup

- Keeps salt from penetrating the slab

- Maintains traction when floors are wet

- Flexes with concrete movement

- Stays looking sharp through years of winter abuse

If your garage is a daily workspace, a storage area, or your main home entry, winter-ready performance isn’t optional—it’s essential.

A Simple Decision Framework

Ask yourself:

What climate am I coating for?

If your winters dip below freezing, epoxy is already at a disadvantage.

Do I want it to last more than a few seasons?

Epoxy often needs touch-ups or full removal within 2–5 years in cold climates.

How much do I rely on my garage?

If peeling or downtime would disrupt your routine, choose the more reliable system.

Is low maintenance important?

Polyurea needs less care, even with salt, snow, mud, and meltwater.

For homeowners in cold-weather regions—especially Pennsylvania—polyurea simply outperforms epoxy in every meaningful way.

Frequently Asked Questions

Can epoxy work at all in cold climates?

Yes, but only with perfect prep and warm-weather install conditions. It’s rarely the best long-term choice.

Does polyurea cost more?

Upfront—yes. But it avoids the common failures that make epoxy more expensive over time.

Will the floor be slippery in winter?

Our flake systems add texture for traction, and a proper topcoat helps maintain grip even when the floor is wet.

How quickly can I use my garage again?

Polyurea and polyaspartic systems cure fast, even in cooler temperatures. We’ll give you a clear timeline before work begins.