Is Polyurea Worth Spending Extra On Over Epoxy?

Key Takeaways

- Polyurea’s flexibility, chemical resistance, and fast cure translate to fewer issues and longer appearance retention under real garage use—value you feel over time.

- Epoxy remains viable for tight budgets and lighter duty, but in Pennsylvania’s freeze–thaw and salt conditions, polyurea is usually the better long-term investment.

If you want a floor that looks sharp on day one, both epoxy and polyurea can deliver it. The question is how that floor holds up once real life happens—hot tires in July, salt and slush in January, dropped tools, and a few years of parking in the same spots. In those conditions, polyurea usually earns its higher price with longer appearance retention, less maintenance, and fewer headaches over time—especially in Pennsylvania.

What the extra cost buys you

Flex without failure. Concrete moves with temperature swings and freeze–thaw cycles. Epoxy is rigid, which is part of its strength but also why it can micro-crack or lift at joints when the slab shifts. Polyurea has a bit of built-in flexibility, so the film is more likely to ride out movement.

Better resistance where garages actually fail. Polyurea systems are known for standing up to hot-tire pickup, road salt, oil, and household chemicals. That combination matters a lot in PA, where winter brine and spring humidity are routine.

Quicker return to service. Polyurea cures fast. Many homeowners appreciate being back in the garage sooner, which is a real cost if you’re juggling limited parking or a crowded driveway.

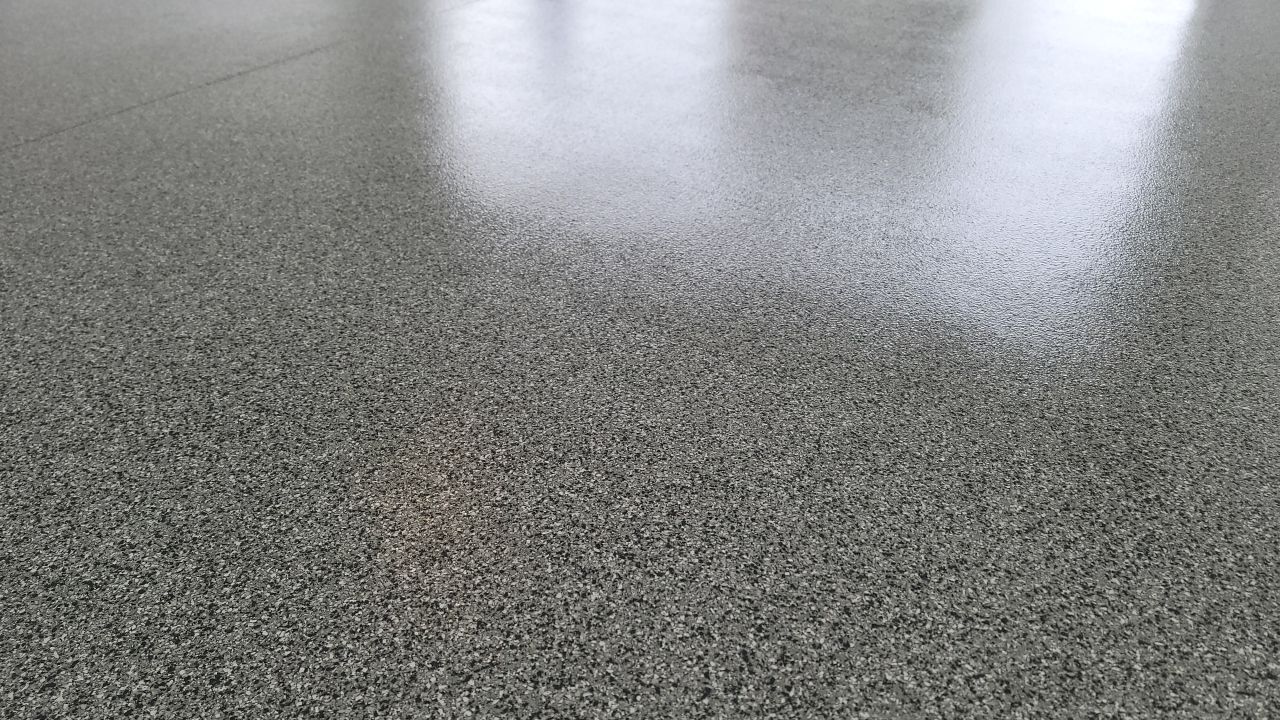

Finish that stays “new” longer. With a full flake broadcast and durable topcoat, polyurea tends to keep its gloss and color without ambering, and flake texture helps hide minor wear in busy traffic lanes.

Where epoxy can still make sense

Epoxy is time-tested, widely available, and can be the right call when:

- You’re on a

tight upfront budget and primarily want a cosmetic refresh.

- The

slab is newer and in excellent condition, with low vapor and minimal movement.

- The garage sees

light duty—more storage and hobbies than daily vehicle use.

If you’re meticulous about surface prep, choose quality materials, and accept that you may need a maintenance topcoat sooner, epoxy can be a perfectly reasonable choice.

A simple, honest comparison

| Factor | Epoxy | Polyurea |

|---|---|---|

| Upfront cost | Lower | Higher |

| Flexibility with slab movement | Low | Moderate |

| Hot-tire / chemical resistance | Good (varies by system) | Excellent |

| UV/color stability | Varies; can amber | Strong |

| Return to service | Slower | Faster |

| Typical longevity under real use | 5–10 yrs (pro-installed, good prep) | Longer intervals between refreshes |

| Best fit | Cosmetic upgrade, lighter use | Daily drivers, PA winters, long-term value |

Note: Lifespan depends heavily on prep, slab condition, and maintenance.

Pennsylvania realities that tilt the math

Our winters bring de-icing salts and slush; shoulder seasons bring humidity swings; older garages often have a bit of vapor drive. Those conditions are exactly where polyurea’s flexibility and chemical resistance show their value. You’ll feel it in fewer touch-ups at hot-tire zones, less staining from salt brine, and a finish that still looks uniform a few years in.

Cost vs. value: how to decide

Ask three questions and the answer tends to reveal itself:

- How long do you plan to stay?

If you’ll be in the home 5+ years (or you want a “do it once, enjoy it” solution), the longer maintenance interval of polyurea usually pays off. - How tough is your usage?

Daily parking while tires are hot, winter salt, projects that create grit or chemical spills—these push toward polyurea. - What’s your tolerance for rework?

If a touch-up every few years is no big deal, epoxy can fit. If you’d rather minimize return visits, polyurea reduces variables.

Maintenance and refresh expectations

Regardless of chemistry, grit is the enemy. Sweep, neutral-clean, and squeegee meltwater during winter. Expect epoxy to need a

maintenance topcoat sooner under normal garage use; polyurea systems often stretch the interval thanks to better abrasion and chemical resistance. Neither system is “maintenance-free,” but polyurea tends to be

lower-maintenance over the same timeline.

Frequently Asked Questions

Is polyurea always worth it?

Not always. If your slab is pristine, your use is light, and budget is tight, epoxy can meet the brief. Polyurea shines when longevity, daily use, and Pennsylvania winters are in the equation.

Will buyers notice the difference at resale?

Most won’t know the chemistry, but they notice a floor that still looks clean and uniform. That helps listings photograph better and reduces “repair credit” conversations.

Can I mix systems—epoxy base with a polyaspartic topcoat?

System compatibility matters more than labels. Many pro polyurea builds use polyaspartic topcoats; the key is a matched system from prep to finish.

What if my slab has moisture?

Address vapor first with testing and, if needed, a moisture-tolerant primer or mitigation step. Neither epoxy nor polyurea is a cure-all for hydrostatic pressure.

Closing Thoughts

If you’re choosing strictly on day-one appearance, both coatings look great. If you’re choosing for

how the floor performs in real life—hot tires, salt, spills, and seasons—polyurea typically justifies the premium, particularly in Pennsylvania. It’s the difference between a finish you admire at installation and one you’re still proud of years later.