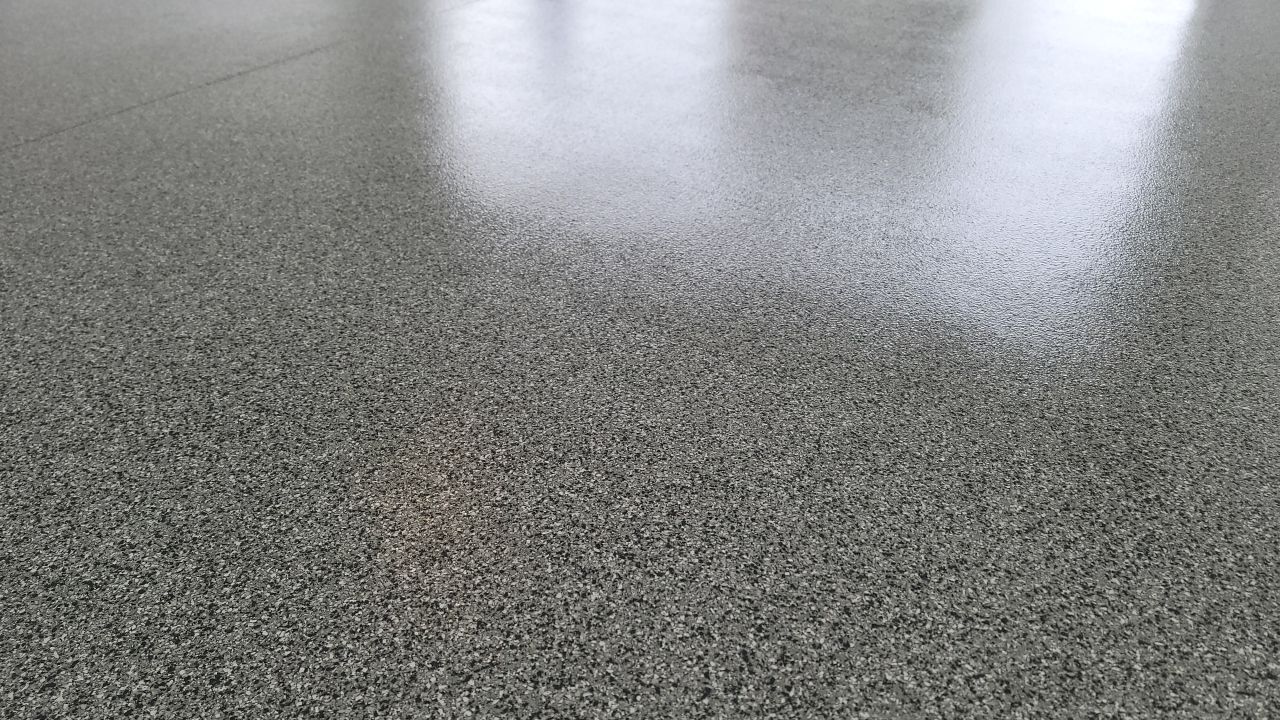

Do Epoxy Floors Need To Be Re-Sealed?

Key Takeaways

- Epoxy floors don’t need annual “resealing”; they benefit from maintenance topcoats when wear shows—often every 5–7 years in typical residential use.

- In Pennsylvania’s salt and freeze–thaw conditions, smart habits (squeegee meltwater, neutral clean) stretch intervals; polyurea systems commonly go even longer between refreshes while keeping gloss and traction.

Sometimes—but not the way a driveway or deck does. A well-installed epoxy garage floor is a film-forming system (primer/body coat/topcoat), not a penetrating sealer that soaks in and fades every season. If the coating was properly prepped and top-coated, you’re usually looking at maintenance topcoats every few years only when wear and tear warrant it, not an annual “reseal.” Many homeowners who want longer intervals and quicker turnarounds choose polyurea systems with polyaspartic topcoats because they hold gloss and traction longer under real garage use.

What “resealing” actually means on a coated floor

On concrete, “sealer” often means a clear liquid that soaks in. Epoxy and polyurea systems are different: they build a protective film over the slab. When people say “reseal” here, they really mean apply a fresh topcoat to restore gloss, traction, and chemical/abrasion resistance. You aren’t starting over; you’re refreshing the wear layer—assuming the base is still bonded and sound.

How to know if your epoxy is ready for a maintenance topcoat

You don’t need a magnifying glass—just a quick read of the surface:

- Persistent dull lanes where car tires track, even after a thorough neutral clean and rinse.

- Micro-scratches that make the floor look hazy under daylight.

- Staining that lifts but ghosts remain, especially from oils or de-icing salts.

- Good adhesion overall, with no widespread peeling—just cosmetic fatigue.

If you’re seeing peel, bubbles, or wide cracks telegraphing through, a simple topcoat won’t fix underlying issues. That calls for selective removal and repair, or a full resurfacing.

Typical timelines (and why they vary)

In a light-use Pennsylvania garage with quality prep and a durable topcoat, many epoxy floors look great for 5–7 years before a refresh makes sense. Busy shops, frequent hot-tire parking, or aggressive cleaning products shorten that. Conversely, meticulous cleaning and smart habits can stretch the interval.

What moves the needle most:

- Surface prep quality. Diamond-ground concrete gives the base coat a profile to lock into; that foundation supports every future refresh.

- Topcoat chemistry. Abrasion-resistant, UV-stable topcoats hold sheen and color longer.

- Winter exposure. Road salt and studded tires increase wear—common across southeastern PA.

- Cleaning routines. Grit is sandpaper; neutral cleaner and a rinse keep the floor from wearing prematurely.

Where polyurea fits

Polyurea systems (often finished with polyaspartic topcoats) are popular when homeowners want longer maintenance intervals and fast return to service. The film has excellent chemical resistance and a touch of flexibility that helps it ride out freeze–thaw movement. In practice, many PA homeowners find they can go longer between topcoat refreshes with polyurea—especially if the floor uses a full flake broadcast that hides micro-wear and maintains traction.

What a proper refresh involves

A maintenance topcoat is straightforward when the base is sound:

- Deep clean and decontaminate (remove oils, silicone residues from tire dressings, and salt film).

- Light mechanical abrade the existing topcoat to promote adhesion.

- Address small chips and scratches, and re-detail edges and steps.

- Roll or squeegee a new topcoat, with traction additive dialed to your preference (often finer in the main bay, slightly coarser at the house step).

Most projects are measured in hours to a day of downtime, not days—especially with fast-curing polyaspartic topcoats.

Pennsylvania realities

Our region’s freeze–thaw cycles and de-icing salts ask more of a topcoat than a dry-climate garage. Two simple habits pay off: squeegee meltwater out after storms and neutral-clean mid-winter to remove salt brine. Those steps reduce the micro-abrasion and chemical load that make floors look tired before their time—so you refresh less often and get more years between topcoats.

Maintenance versus reseal: quick decision guide

If the floor is

intact but dull, a maintenance topcoat is the efficient, cost-effective path.

If you see

widespread lifting, moisture blisters, or structural cracks, solve those first—then choose the system (epoxy or polyurea) that suits how you actually use the garage.

Frequently Asked Questions

How often should I plan on resealing an epoxy floor?

There’s no fixed schedule. Many well-installed floors go 5–7 years before a refresh; heavy use can shorten that, good care can extend it.

Will a new topcoat fix peeling?

No. Topcoats restore the wear surface. Peeling points to adhesion problems beneath; those areas need removal and proper repair.

Can I DIY the refresh?

Possible on small, intact floors if you’re set up to clean, abrade, and apply correctly. Most homeowners prefer a pro to ensure adhesion and to dial in traction additives.

Is polyurea “maintenance-free”?

Nothing is. But polyurea with a quality topcoat typically holds appearance and traction longer, so refreshes are less frequent—especially in winter-hardy garages.