Media Blasting vs Chemical Stripping vs Power Washing Guide

Key Takeaways

- Surface preparation method directly determines coating lifespan—choosing wrong can cut performance in half

- Each method serves different applications: power washing for light cleaning, chemical stripping for delicate surfaces, media blasting for comprehensive preparation

- Total project cost includes method expense plus long-term performance—proper preparation pays for itself through extended coating life

The success of any commercial coating project isn't determined by the paint you choose or even the skill of the applicator—it's determined by what happens before the first drop of coating touches your surface. Surface preparation accounts for up to 80% of coating performance, yet it's the area where many contractors cut corners to appear more competitive.

When evaluating surface preparation options for your commercial project, you'll encounter three primary methods: power washing, chemical stripping, and media blasting. Each serves specific applications, and choosing the wrong approach can compromise your entire investment. Here's your complete guide to making the right decision for your project.

Understanding the Surface Preparation Challenge

Commercial surfaces accumulate years of environmental exposure, previous coatings, corrosion, and contamination that prevent new coatings from properly adhering. Unlike residential projects where a quick wash and light sanding might suffice, commercial applications demand preparation methods that address the full scope of surface conditions.

Poor surface preparation is the leading cause of premature coating failure. A coating applied over inadequately prepared surfaces may look acceptable initially, but it will fail within months rather than years, requiring complete removal and reapplication at costs that often exceed the original project budget.

The goal of proper surface preparation is creating a clean, sound substrate that allows maximum adhesion for your new coating system. Different contamination types and surface conditions require different approaches, and understanding these requirements is crucial for project success.

Power Washing: When Basic Cleaning Is Sufficient

Power washing represents the most basic level of surface preparation, using high-pressure water to remove dirt, grime, mildew, and loose materials from surfaces. This method works well for maintenance cleaning and light preparation but has significant limitations for comprehensive coating projects.

Power washing excels in specific applications. It effectively removes environmental contamination like dirt, dust, and biological growth from surfaces. It can eliminate chalky residue from weathered surfaces and wash away salt deposits and other water-soluble contaminants. The process requires minimal setup and can cover large areas quickly, making it cost-effective for basic cleaning applications.

However, power washing has clear limitations that make it inappropriate for many commercial coating projects. It cannot remove well-adhered existing coatings, has minimal impact on rust and corrosion, provides no surface profile for coating adhesion, and may actually drive contaminants deeper into porous surfaces. Additionally, the process can damage softer materials and may require extended drying time before coating application.

Power washing works best for annual maintenance cleaning, pre-painting cleaning on previously prepared surfaces, removing surface contamination before other preparation methods, and cleaning areas where coating adhesion isn't critical. The typical cost ranges from $0.15 to $0.30 per square foot, making it the most economical option when appropriate.

Chemical Stripping: Precision Removal for Delicate Applications

Chemical stripping uses specialized solvents and caustic solutions to dissolve existing coatings and contamination without mechanical impact. This method offers precision control and works well on delicate surfaces where mechanical preparation might cause damage.

Chemical stripping provides several advantages for appropriate applications. It can remove multiple coating layers simultaneously, works on complex geometries and detailed surfaces that mechanical methods can't reach effectively, and provides selective removal capability for specific coating types. The process generates no dust or debris during application and can be highly effective on lead-based paints and specialized coatings.

The method also presents significant limitations and considerations. Chemical strippers require extensive safety protocols due to health and environmental hazards. Disposal of waste materials involves specialized handling and can be costly. The process requires neutralization steps before coating application and may not provide adequate surface profile for optimal adhesion. Weather conditions significantly impact effectiveness, and worker safety requirements increase project complexity.

Chemical stripping works best for historic restoration projects where surface preservation is critical, detailed architectural elements that can't be mechanically prepared, lead paint removal in occupied buildings with strict containment requirements, and selective coating removal where substrate protection is paramount. Costs typically range from $1.50 to $4.00 per square foot, depending on coating types and safety requirements.

Environmental and safety considerations make chemical stripping less common in routine commercial applications. Proper containment, worker protection, and waste disposal requirements often make this method cost-prohibitive except for specialized applications where other methods aren't feasible.

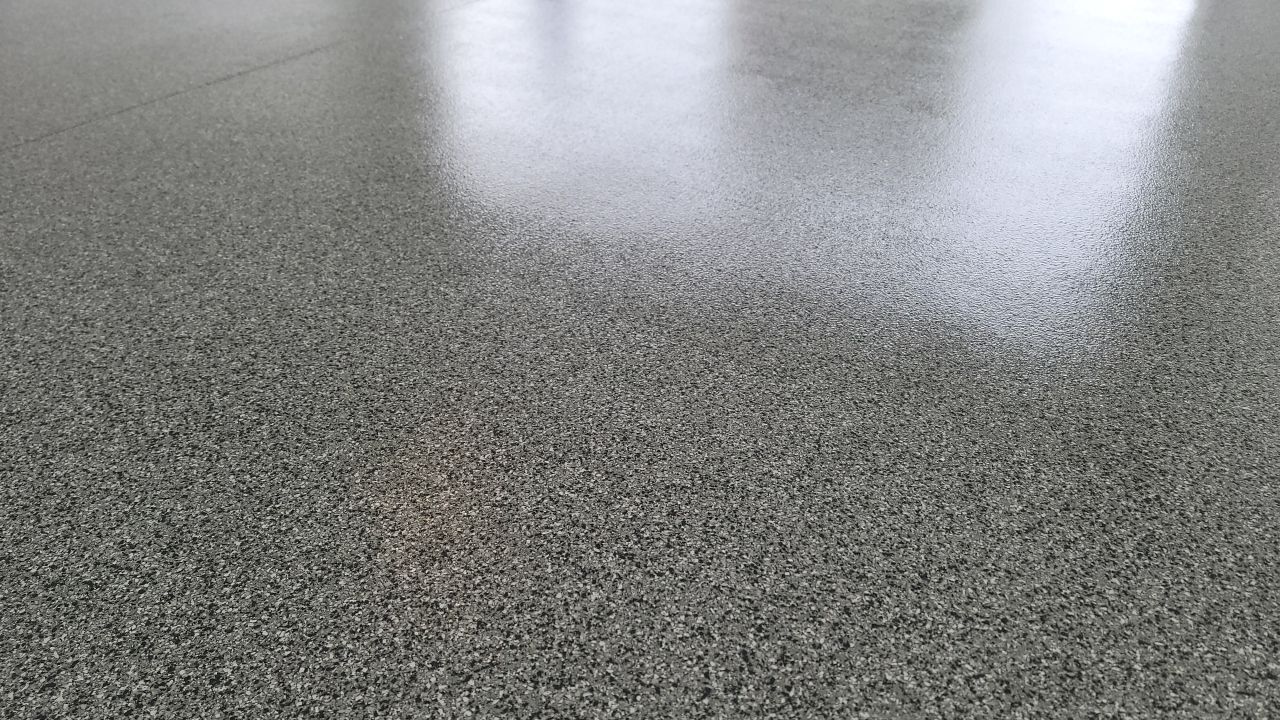

Media Blasting: Comprehensive Preparation for Maximum Performance

Media blasting represents the most thorough surface preparation method, using compressed air to propel abrasive media against surfaces, removing coatings, corrosion, and contamination while creating optimal surface profile for coating adhesion.

The versatility of media blasting comes from the variety of available media types, each suited to specific applications. Steel grit provides aggressive cutting action for heavy corrosion and thick coatings. Aluminum oxide offers excellent cutting power with recyclable media. Glass beads provide gentle cleaning for delicate surfaces. Plastic media works well for paint removal without substrate damage. Walnut shells and corn cob media offer environmentally friendly options for sensitive applications.

Media blasting delivers comprehensive surface preparation that other methods cannot match. It completely removes existing coatings, rust, and contamination in a single operation. The process creates optimal surface profile for coating adhesion, can be adjusted for different substrate types and conditions, and provides immediate coating readiness upon completion. Quality control is straightforward with visual standards that ensure consistent results.

The method does require specialized equipment, trained operators, and comprehensive containment systems. Dust generation necessitates proper filtration and environmental controls. Surface protection for adjacent areas becomes critical, and some media types may embed in softer substrates if improperly applied.

Media blasting excels in heavy-duty industrial applications, structural steel preparation, concrete surface preparation, removal of multiple coating layers, and situations requiring maximum coating adhesion and longevity. Costs typically range from $2.00 to $6.00 per square foot, depending on surface conditions and media requirements.

Comparing Total Project Economics

While initial preparation costs vary significantly between methods, total project economics must consider both immediate expenses and long-term performance. A coating applied over properly blasted surfaces may last 15-20 years, while the same coating over power-washed surfaces might fail within 3-5 years.

Consider a 10,000 square foot commercial building exterior requiring coating. Power washing preparation costs $2,000, chemical stripping costs $25,000, and media blasting costs $35,000. However, the coating applied over power-washed surfaces requires replacement every 5 years, while media-blasted surfaces provide 15-year performance.

Over a 15-year period, the power washing approach requires three complete projects totaling $150,000+, while media blasting requires one project at $85,000. The "expensive" preparation method actually costs 43% less over the coating's intended lifespan while providing superior appearance and protection throughout.

Hybrid Approaches: Combining Methods for Optimal Results

Many commercial projects benefit from combining preparation methods to address different surface conditions and requirements. A typical approach might use media blasting for heavily contaminated or corroded areas, chemical stripping for detailed architectural elements, and power washing for final cleaning before coating application.

This hybrid approach optimizes both performance and cost by matching preparation intensity to surface requirements. Areas requiring maximum coating adhesion receive thorough mechanical preparation, while less critical areas receive appropriate but less expensive treatment.

Project planning becomes crucial when combining methods. Scheduling must accommodate different preparation requirements, containment systems may need modification between methods, and quality control standards must address varying preparation levels across the project.

Environmental and Regulatory Considerations

Modern surface preparation projects must address environmental regulations and sustainability concerns that significantly impact method selection. Media blasting generates recyclable waste streams when appropriate media is selected. Steel grit and aluminum oxide can be reclaimed and reused multiple times, reducing overall environmental impact.

Chemical stripping creates hazardous waste requiring specialized disposal, increasing both cost and environmental impact. Solvent vapors may trigger air quality restrictions, and runoff containment becomes critical for environmental protection.

Power washing generates contaminated water that may require treatment before disposal, particularly when removing lead-based paints or industrial contamination. Runoff control and water treatment add costs that aren't immediately apparent in initial estimates.

Worker safety regulations increasingly favor mechanical preparation methods over chemical approaches. OSHA requirements for chemical stripping include extensive personal protective equipment, air monitoring, and medical surveillance that add significant project costs.

Making the Right Choice for Your Project

Selecting appropriate surface preparation requires evaluating multiple factors beyond initial cost. Consider your coating performance requirements, environmental conditions, substrate conditions, regulatory constraints, and total project timeline when making decisions.

For routine maintenance projects on previously prepared surfaces, power washing may provide adequate preparation at minimal cost. For maximum coating performance on critical assets, media blasting delivers preparation that supports long-term success. For specialized applications involving delicate surfaces or lead paint removal, chemical stripping may be necessary despite higher costs.

Quality contractors will assess your specific conditions and recommend preparation methods based on performance requirements rather than initial cost considerations. Be wary of contractors who default to the least expensive preparation method without thoroughly evaluating surface conditions and performance expectations.

Quality Control and Specification Standards

Professional surface preparation follows established standards that ensure consistent results regardless of method chosen. The Society for Protective Coatings (SSPC) and NACE International provide specifications that define acceptable preparation levels for different applications.

Media blasting standards include SSPC-SP 10 (Near-White Metal) for maximum performance applications and SSPC-SP 6 (Commercial Blast) for general industrial use. Power washing follows SSPC-SP 1 standards with specific requirements for surface cleanliness. Chemical stripping must meet SSPC-SP 8 standards with additional requirements for neutralization and surface preparation.

Quality control during preparation includes visual inspection against established standards, surface profile measurement using specialized gauges, contamination testing to verify cleanliness, and documentation of conditions before and after preparation.

The Bottom Line: Preparation Determines Performance

Surface preparation isn't an area where cutting corners pays off. The method you choose directly determines coating performance, longevity, and total project cost over the coating's intended lifespan. Understanding the capabilities and limitations of each approach enables informed decisions that support both immediate budget requirements and long-term performance goals.

Power washing works for basic cleaning and maintenance applications but cannot provide the thorough preparation required for maximum coating performance. Chemical stripping offers precision removal for specialized applications but carries environmental and safety costs that limit routine use. Media blasting delivers comprehensive preparation that supports optimal coating performance and longevity.

The question isn't which method costs least initially—it's which approach delivers the performance your project requires at the lowest total cost of ownership. Professional contractors understand this distinction and will recommend preparation methods based on your specific requirements rather than simply offering the cheapest option.

Your commercial facility deserves surface preparation that supports long-term success. Choose methods based on performance requirements, and partner with contractors who understand that proper preparation is an investment in your facility's future, not just an expense to minimize.

Need expert guidance on surface preparation for your commercial project? Contact PR Commercial Painting to discuss your specific requirements. Our team specializes in matching preparation methods to performance requirements, ensuring your coating investment delivers maximum value and longevity.