Should I DIY or Hire a Professional For My Epoxy Garage Floor?

Key Takeaways

- DIY epoxy can refresh a floor short-term, but real-world garage use (hot tires, road salt, freeze-thaw) exposes its limits; failures often erase any upfront savings.

- For a long-lasting, low-maintenance result in Pennsylvania, a professionally installed polyurea system offers the best balance of durability, stain resistance, and appearance.

When a garage floor is stained, dusty, or just plain tired, epoxy DIY kits are tempting. The box promises a weekend project and a shiny finish—how hard can it be? The truth: getting a coating to actually bond, level, and last is where most DIY jobs fall short. And while epoxy is the word everyone knows, it’s not always the best fit for how Pennsylvania garages are used year-round.

Below, we’ll break down what DIY really involves, when epoxy makes sense, why many homeowners ultimately choose a professional polyurea system, and how to decide what’s right for your home.

What DIY Epoxy Really Requires

DIY sounds simple on paper—clean, etch, roll. In reality, the result hinges on the concrete’s condition and how meticulously the surface is prepared.

- Moisture & cracks: Concrete needs testing for moisture and repaired where it’s spalled, pitted, or cracked. Skipping this step leads to bubbling or peeling.

- Surface prep: Light “etching” rarely equals a proper profile. Professional crews mechanically grind the slab so the coating can key into it.

- Timing & cure windows: You’re racing temperature, humidity, and recoat windows. Miss them and you’re looking at weak adhesion or lap lines.

- Chemicals & safety: Acids, solvents, and dust from grinding all require PPE and containment most garages aren’t set up for.

DIY can still work for an even, newer slab when the goal is a short-term refresh. But if you need a coating that stands up to daily driving, hot tires, road salt, and spills, epoxy DIY is often a gamble.

Where Epoxy Fits—and Where It Struggles

Epoxy has been used for decades and looks great on day one. Its weak spots tend to show up under real-life garage use:

- Rigid composition =

less forgiving when concrete moves (freeze-thaw, settling).

- Can be

more prone to hot-tire pickup (the coating lifts where tires sit).

- Chemical and UV sensitivity can lead to staining and discoloration over time.

If your priority is a quick cosmetic improvement at the lowest upfront cost, epoxy can meet the brief. If you want durability + low maintenance, there’s a reason more homeowners in PA are moving to polyurea systems.

Why Many Homeowners Choose Polyurea (Over Epoxy)

Polyurea is engineered to flex with concrete, resist chemicals, and shrug off abrasion from daily use. It’s the system we install most for residential garages because it balances performance and appearance:

- Flexibility helps the coating ride out temperature swings and micro-movement without cracking.

- Stain and chemical resistance holds up to oil, gas, de-icing salts, and household cleaners.

- Fast return to service with professional installation—less disruption to your routine.

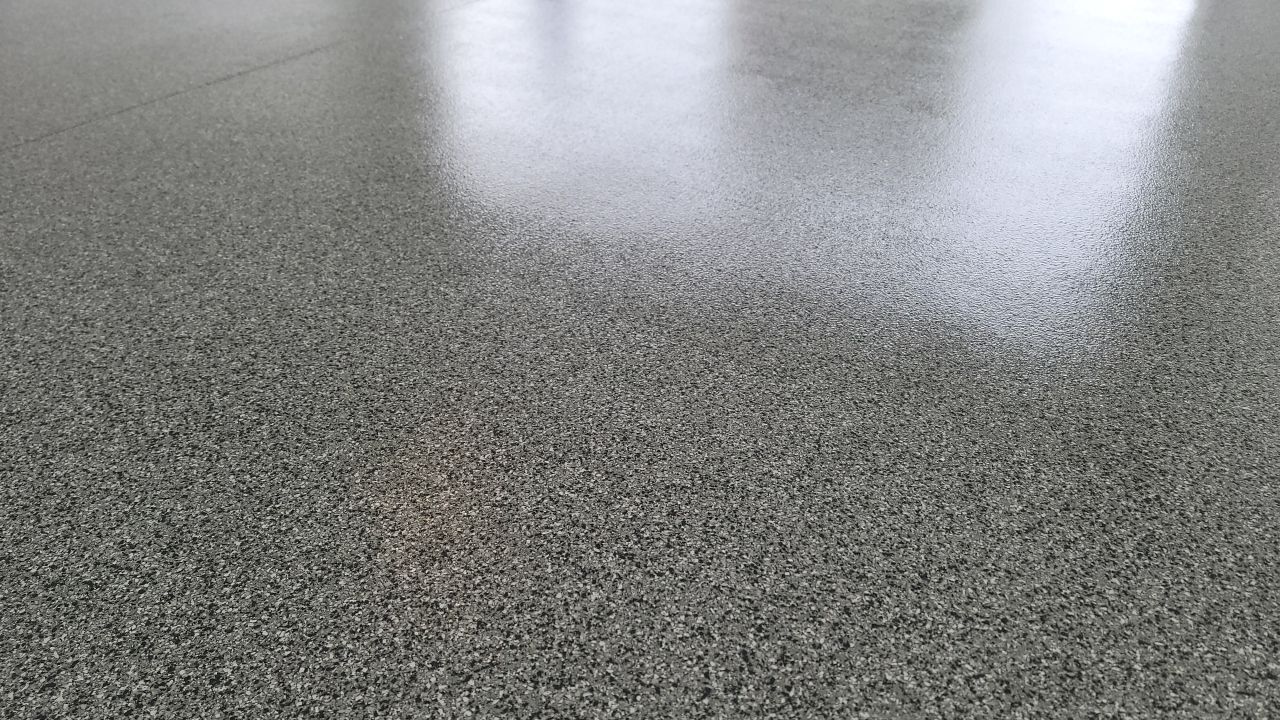

- Premium finish options with flake systems that hide imperfections and provide light texture for traction.

If you want a garage floor you don’t have to worry about each winter, polyurea is typically the long-term value choice. You can see how we approach preparation, coatings, and topcoats on our garage floor coatings page.

The Real Cost of “Saving Money” on DIY

The sticker price of a kit doesn’t include the things that prevent failure:

- Grinding & dust control equipment (or paying to remove failed coating later).

- Concrete repair materials for pits, cracks, and control joints.

- Topcoats and flakes (often add-ons in DIY kits).

- Your time, storage, and downtime while the garage is out of commission.

When early peeling or staining leads to a re-do, what looked “cheap” can quickly cost more than a professional system. For a deeper breakdown, explore the hidden costs of budget coatings over time.

What a Professional Install Actually Adds

Hiring a pro isn’t just about better materials; it’s about process and control:

- Assessment: Moisture checks, slab condition, and repair plan so you’re not coating over problems.

- Mechanical prep: Diamond grinding to the proper profile for strong adhesion.

- System design: Matching products (e.g., polyurea base + polyaspartic topcoat) to your goals and environment.

- Clean edges & details: Stem walls, steps, expansion joints—done neatly and consistently.

- Predictable timeline: Clear cure windows, faster return to service, and less disruption.

If you’re comparing materials, our breakdown of epoxy, polyurea, and polyaspartic clarifies how each performs in a working garage.

Built for Pennsylvania Garages

Southeastern Pennsylvania garages see freeze-thaw cycles, tracked-in road salt, and wide humidity swings. Those are tough on coatings.

Polyurea’s flexibility and chemical resistance make it a strong fit for our climate. Combine that with professional prep and you’ll get a floor that resists hot-tire pickup in July and salt intrusion in January—without turning maintenance into a part-time job.

A Simple Decision Framework

Ask yourself:

- How long do I need it to last? If under 2–3 years, a budget epoxy refresh might be fine. If 5–10+ years, consider a professional polyurea system.

- What’s my tolerance for risk and re-work? If peeling means a full removal and start-over, you’ll want to minimize that risk up front.

- What’s the true cost of downtime? Moving cars, tools, and storage twice isn’t free—time is money.

- Do I want a flawless finish? Flake broadcast with pro-grade topcoats hides imperfections and levels out beautifully.

When longevity, appearance, and low maintenance matter,

hire a professional—and strongly consider

polyurea. If you’re ready to weigh options, start with our overview of garage floor coatings.

Frequently Asked Questions

Is epoxy ever the right choice?

Yes—if you’re after a short-term cosmetic update on a budget and the slab is in great shape. Just set expectations on durability.

Why is polyurea more expensive up front?

You’re paying for higher-performing chemistry and professional prep/application. It typically costs less over time because it holds up better.

Will a professional job really look different?

Usually, yes. Grinding, repairs, and a proper flake/topcoat system deliver a more uniform finish, clean edges, and better traction.

How fast can I use my garage again?

With professional scheduling and cure management, most homeowners are back to normal quickly. We’ll give you a clear, realistic timeline for your project.

What maintenance is required?

Just sweep and occasionally mop. Avoid harsh solvents and use a neutral cleaner as needed. We’ll leave you with simple care guidelines.

Closing Thoughts

If you love projects and accept some risk, a DIY epoxy can be a fun weekend—in the right conditions. If you want a

beautiful, durable, low-maintenance floor that handles Pennsylvania’s climate and daily use, a

professionally installed polyurea system is the smarter investment.