The Hidden Costs of Cheap Garage Floor Coatings

Key Takeaways

- Budget coatings may look fine at first but often fail quickly, costing more in repairs, recoats, and frustration.

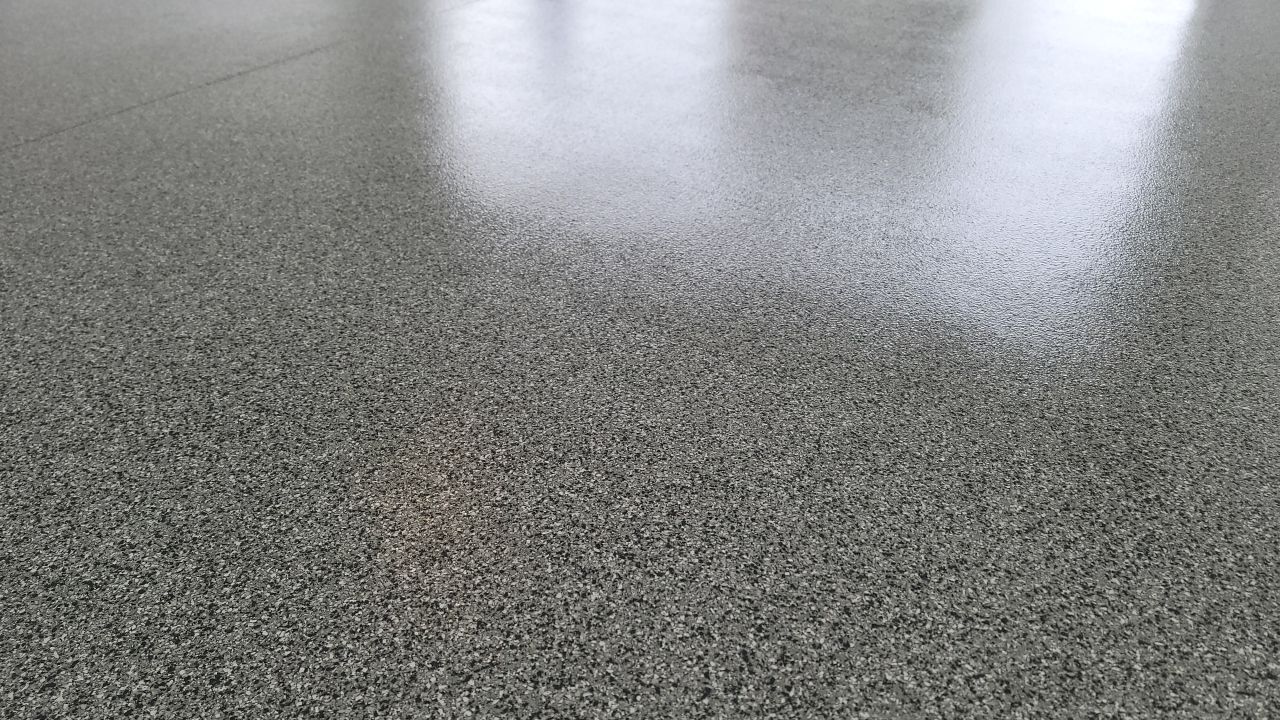

- Professional-grade systems, like those installed by PR Painting, provide lasting durability, stain resistance, and a finish that enhances your home for years.

It’s easy to be tempted by the lowest price when researching garage floor coatings. After all, it’s just a garage floor, right? But when coatings start peeling, yellowing, or breaking down within a year or two, the “cheap” option suddenly looks very expensive.

At PR Painting, we bring commercial-grade expertise into residential garages across Pennsylvania. We’ve seen what happens when cut corners catch up with homeowners. This guide explains the hidden costs behind cheap coatings—and why investing in professional installation protects your garage, your investment, and your peace of mind.

1. Skipped or Improper Surface Preparation

The single biggest difference between a professional job and a budget kit is surface preparation. Many low-cost options skip proper grinding or repair work, relying instead on quick fixes like acid etching.

The result? Poor adhesion. Once the coating lifts, moisture and road salt get underneath, accelerating failure. Re-doing a floor means paying for removal, re-prep, and a new system—all costs that could have been avoided with professional prep from the start.

2. Low-Grade Materials That Don’t Hold Up

Cheap coatings are often little more than decorative paint. They might look good initially, but they don’t stand up to:

- Hot tires pulling the coating up.

- Pennsylvania winters, where de-icing salts and freeze-thaw cycles wreak havoc.

- Spills and stains from oil, gas, or household chemicals.

By contrast, PR Painting uses advanced coating technologies—including polyurea systems with enhanced flexibility and chemical resistance—so floors resist wear and keep their appearance for years.

3. Add-On Expenses After the Initial Quote

That low sticker price usually doesn’t include everything. Protective topcoats, decorative flakes, or stain-resistant finishes are often sold as add-ons. By the time you’ve upgraded to what you actually want, the “cheap” option isn’t so cheap anymore.

Professional companies like PR Painting are transparent about process and cost: assess, plan, prep, coat, and maintain. That clarity prevents nasty surprises mid-project.

4. Lost Time and Repeat Disruption

When low-cost coatings fail, your garage is out of service all over again. That’s more time spent moving cars, storing belongings, and waiting for another cure cycle.

PR Painting’s process ensures coatings are installed correctly the first time and come with simple maintenance guidelines to keep them looking great long term. Instead of repeated downtime, you enjoy your garage without interruptions.

5. The Lifetime Cost Comparison

Let’s compare what homeowners often experience over a decade:

- Cheap Coating Path:

- Initial install: low price

- Failure in 1–3 years → re-do costs

- Multiple disruptions, additional repairs

- Total: several times the original estimate

- Professional Coating Path:

- Initial install: higher upfront

- Proper prep + advanced coatings = long-term performance

- Minimal maintenance, no early re-dos

- Total: one investment that lasts

In short, a professional system may cost more upfront, but it saves thousands of dollars and countless headaches over time.

Why Homeowners in Pennsylvania Choose PR Painting

PR Painting isn’t new to coatings—we’ve been perfecting them in commercial and industrial facilities where durability is non-negotiable. That experience carries over into your home garage.

- Commercial-grade expertise: we know how to handle challenging concrete conditions and moisture issues.

- Advanced technology: beyond epoxy, we use

polyurea systems designed to resist hot tire pickup, stains, and heavy traffic.

- Precision prep and application: ensuring your floor bonds right and lasts.

- Proven process: assess → plan → prep & coat → maintain.

Our goal is simple: to deliver the best garage transformation you’ve ever experienced.

Frequently Asked Questions

Why do cheap garage floor coatings peel?

They often skip proper surface preparation. Without grinding and repair, coatings can’t bond to the concrete and peel under heat, moisture, or stress.

Are professional coatings really different from DIY kits?

Yes. Kits may cover up stains temporarily, but professional systems resist hot tires, chemicals, and wear for years.

What types of coatings does PR Painting use?

We go beyond basic epoxy, using advanced polyurea systems with superior flexibility, chemical resistance, and long-term performance.

How do I maintain a coated garage floor?

Simple sweeping and occasional mopping are usually all it takes. PR Painting provides clear maintenance guidelines after installation to keep your floor looking great.

Closing Thoughts

A garage floor should be more than just a cover-up—it should be a lasting improvement that adds value to your home. Cheap coatings may save money upfront, but the hidden costs of repairs, recoats, and downtime quickly outweigh any short-term savings.

By choosing PR Painting’s

commercial-grade expertise and proven process, you get a garage floor that looks beautiful, performs under real-life conditions, and stands the test of time.